Solutions for the pellet process

Optimize your pellet process with Saalasti technology and achieve up to 20–30% lower drying energy consumption.

Optimize your pellet process with Saalasti technology and achieve up to 20–30% lower drying energy consumption.

What if you could significantly reduce your energy consumption for drying – while also ensuring a consistent quality of your raw material?

In pellet production, even small changes in raw material handling can dramatically impact energy consumption, process stability, and product quality. With solutions like Hippo, you can achieve not only lower energy use but also more uniform moisture content, leading to a more stable and efficient production process.

Saalasti offers advanced solutions for biomass processing and mechanical dewatering, enabling pellet producers to improve profitability, mitigate operational risks, and produce high-quality pellets at lower production costs. Whether you’re working with sawdust, woodchips, or mixed biomass, our solutions provide you with better control and more reliable results.

Our machines are designed to withstand the demanding conditions of industrial-scale pellet production, ensuring stable operation and a long equipment lifespan.

Material losses and inconsistent feedstock can reduce pellet yield and quality, and limit profitability. Mechanical dewatering and consistent biomass properties help ensure that a higher percentage of incoming material becomes a high-quality product.

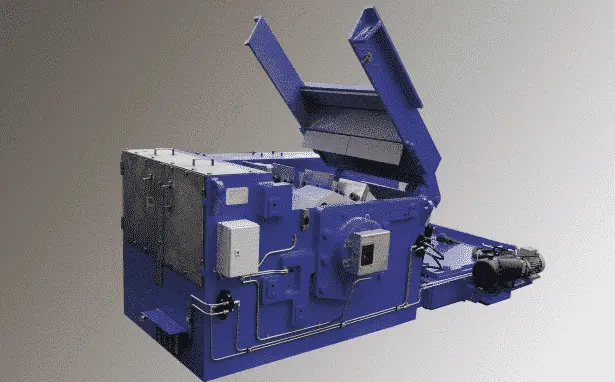

The Saalasti High-Pressure Press Hippo enhances feedstock consistency and minimises material loss during drying and pelletizing by mechanically removing water. This means less waste, a higher-quality end product, and better use of raw materials, especially when working with challenging biomass types.

More efficient use of raw materials

Consistent production throughout the year

Improved pellet yield and consistent quality

Better utilization of challenging biomass

Mechanical dewatering with Saalasti High-Pressure Press Hippo enables more stable material and better product quality.

Drying wet biomass is one of the most energy-intensive stages in the pellet production process. By removing water mechanically before thermal drying, energy consumption can be reduced significantly, along with emissions and fuel costs.

With the Saalasti High-Pressure Press Hippo, your pellet plant can achieve substantial energy savings by increasing the dry solids content of biomass before drying.

Saalasti technology has been proven to reduce energy consumption by up to 1.19 megawatt-hours per ton of biomass received, delivering a significant impact on both cost efficiency and sustainability.

Up to 20–30% lower drying energy consumption

Up to 1.19 MWh of energy saved per ton of received biomass

Reduced fuel usage and CO₂ emissions

Lower operating costs

Saalasti technology has been proven to reduce energy consumption by up to 1.19 megawatt-hours per ton of biomass.

Mechanical dewatering with Saalasti High-Pressure Press Hippo reduces the thermal drying load, allowing more material to pass through the dryer in less time. This directly increases production capacity without the need for additional drying equipment.

With drier and more stable feedstock, pellet plants can produce more pellets per hour and operate closer to full capacity, even during peak demand. Improved process stability also reduces downtime and unplanned stoppages.

Increased pellet output with existing equipment

Shorter drying time per tonne of biomass

Better utilization of installed capacity

Fewer process interruptions and higher uptime

When mechanical dewatering minimizes the load on your thermal dryer, the freed-up drying capacity becomes available for processing additional biomass.

Our most important solution for pellet producers. Hippo mechanically removes water from biomass before drying, reducing energy consumption, increasing dryer capacity, and improving process stability.

For precise biomass chipping to the required particle size. Ensures optimal material properties for drying and pelletizing.

Heavy-duty crusher for reducing biomass materials into consistent material. Ideal for processing bark, logging residues, and other challenging feedstocks.

Saalasti delivers proven technology for biomass processing in pellet production. Our equipment is designed for continuous operation, heavy-duty use, and maximum process control.

Saalasti is a global leader in biomass processing technology. With decades of experience and continuous innovation, we offer pellet producers solutions that deliver measurable operational and financial benefits.

The Hippo press removes approximately half of the wood’s water content, enabling a major capacity boost without the need for more thermal energy – which was the primary reason behind van Roje’s investment in the technology.

Many Saalasti machines have been operating continuously since the 1980s; long-term reliability starts with expert maintenance.

From preventive service and spare parts to modernization projects, Saalasti lifecycle services help pellet producers maximize equipment performance and minimize unplanned downtime.

With decades of experience and hundreds of machines in operation worldwide, our service team knows what works in pellet plants. We combine technical expertise with insight from hundreds of factories and real-life operating conditions. This results in a maintenance program that perfectly fits your plant’s needs.

Saalasti lifecycle services ensure that the machinery remains reliable for decades.

Want to hear more about mechanical dewatering and Saalasti’s other solutions? Fill out the form below and we’ll get back to you within two business days.

"*" indicates required fields